"How much essential oil goes in a roller?" is the first question new brands ask. But the second question—and the one that determines product success—is: "Will it leak or get stuck?"

The correct ratio for a standard 10ml roller is typically a 1%–5% dilution (2–10 drops essential oil) in a carrier oil, aligning with Tisserand Institute safety guidelines1. However, for B2B formulators, ensuring your product meets IFRA standards2 requires more than just safety—the viscosity of your carrier oil must match your roller ball type to ensure smooth application without leakage.

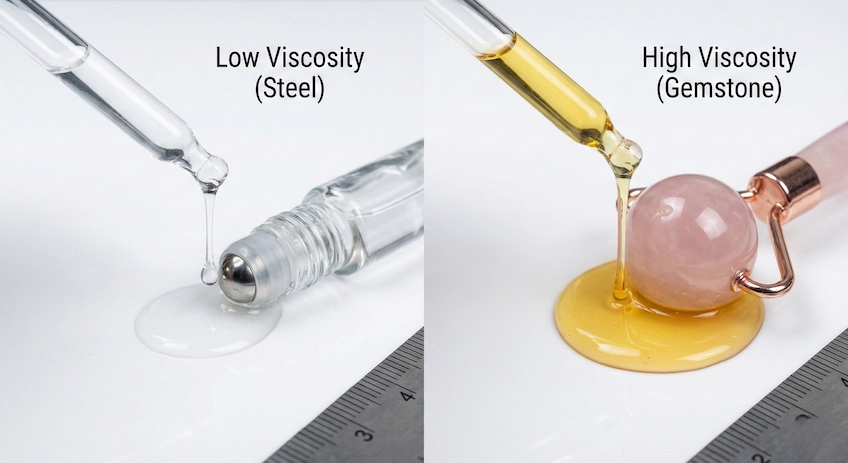

At ECO-BAMBOO, we help aromatherapy brands choose the right packaging hardware3. A thin, watery blend needs a tight-fitting stainless steel mechanism, while a thick, resinous blend flows better with a gemstone or glass ball4.

The Physics of Flow: Steel vs. Glass vs. Gemstone

The "fitment" (the gap between the ball and the housing) dictates the flow rate. To help you choose, we have compiled a compatibility guide based on carrier oil viscosity:

📋 Carrier Oil & Roller Ball Compatibility Table

| Carrier Oil / Base | Viscosity | Recommended Ball Type | Why? |

|---|---|---|---|

| Fractionated Coconut Oil | Low (Watery) | Stainless Steel | Tight fit prevents leaking/dripping. |

| Alcohol (Perfume) | Very Low | Stainless Steel | Precision machining is required for thin fluids. |

| Jojoba / Almond Oil | Medium | Steel OR Gemstone | Versatile; works well with both mechanisms. |

| Castor / Vitamin E | High (Thick) | Gemstone / Glass | Smoother surface helps thick oil glide. |

| Resin Blends (Vetiver) | Very High | Gemstone / Glass | Steel balls may get "stuck" with sticky oils. |

1. Stainless Steel Balls (The Industry Standard)

- Best for: Thin, non-viscous liquids.

- Mechanism: Steel is machined to precise tolerances. It sits tight in the housing, preventing low-viscosity fluids from dripping out.

2. Glass & Gemstone Balls

- Best for: Medium to high viscosity blends.

- Mechanism: These balls often have a slightly looser fitment or smoother surface tension, allowing thicker oils to glide around them.

- Bonus: Our gemstone rollers4 (Rose Quartz, Amethyst) add a "healing crystal" marketing angle to your product.

How to Test Your Blend for Leaks (The Vacuum Test)

Before ordering 10,000 units, perform this simple stress test using our essential oil bottles5:

- Fill: Fill the roller bottle 90% full (leave air gap).

- Heat: Place it in a warm environment (simulating a hot delivery truck).

- Invert: Store it upside down for 24 hours on a white paper towel.

- Vacuum Check: Roll it on your skin. Does it release oil immediately? Or do you have to shake it? (Shaking = Fitment too tight).

Frequently Asked Questions (FAQ) for Formulators

Q: Why is my roller bottle leaking? A: Usually, the oil is too thin (low viscosity) for the ball fitment. If using Fractionated Coconut Oil, switch to a high-precision Stainless Steel ball housing.

Q: Why is my roller ball stuck/not rolling? A: The oil is likely too sticky or thick (e.g., Castor Oil). The friction is too high for a tight steel ball. Switch to a Gemstone or Glass ball mechanism for better glide.

Conclusion

Packaging isn't just a container; it's an applicator. Don't let a generic roller ball ruin your premium formula. Match your viscosity to the hardware.

Need packaging for serums instead? Check out our bamboo dropper bottles6 for precise dosage.

💧 Find Your Perfect Fitment

Request a sample kit with both Steel and Gemstone mechanisms to test your formula.

Tisserand Institute - Essential Oil Safety Guidelines. ↩

IFRA - Standards for Safe Use of Fragrance Materials. ↩

View our classic Glass Roller Bottles with Bamboo Lids. ↩

Explore our luxury Gemstone Roller Bottles with Bamboo caps. ↩

Browse all Bamboo Essential Oil Bottle options. ↩

Discover Bamboo Dropper Bottles for serums and tinctures. ↩