You see bamboo products everywhere, from flooring to t-shirts. But how is a hollow grass stalk turned into a solid, durable product? This knowledge gap makes it hard to choose truly high-quality, sustainable materials1.

Bamboo manufacturing begins by harvesting and drying the natural plant. It is then either cut into strips and laminated under pressure to create solid "bamboo wood," or it is processed mechanically or chemically to extract fibers for making textiles like rayon or bamboo linen.

The first time I visited a bamboo processing facility, I was amazed. On one side of the plant, raw, green stalks of bamboo were coming in from the fields. On the other side, perfectly finished, high-precision cosmetic components were being packaged for shipment. Seeing that transformation from a natural plant into an engineered product with my own eyes was incredible. It showed me that "manufacturing" isn't a single process; it's a journey. Understanding that journey is the key to understanding the material itself.

What is the manufacturing process of bamboo?

You know bamboo starts as a plant. But what are the crucial first steps that happen before it can become a cosmetic lid or a piece of flooring? The initial stages are critical.

The process begins with selectively harvesting mature bamboo culms, typically 3-5 years old. These are then cut to length and dried to a specific moisture content. This fundamental preparation ensures the material is stable, strong, and ready for further manufacturing.

The quality of any finished product depends entirely on the quality of its raw materials and initial prep work. As a designer, you know this principle well from mold making and product design. The same is true for bamboo. At BambooPackage, we are obsessed with these first steps because they lay the foundation for everything that follows. A shortcut here will always show up as a defect in the final product.

The First Steps: From Forest to Factory

The journey from a living plant to a workable raw material involves a few essential stages. Each one is vital for the strength and stability of the final product.

- Selective Harvesting: We don't clear-cut forests. Instead, individual bamboo culms are chosen and harvested by hand once they reach maturity in 3-5 years. This allows the root system to remain intact, ready to send up new shoots. This practice is what makes bamboo such a rapidly renewable resource.

- Cutting and Splitting: The harvested culms are cut into manageable lengths. They are then split lengthwise into strips, which exposes the inner material and removes the outer green "skin" and inner knots.

- Treatment: The raw strips are briefly boiled or steamed. This isn't for shaping; it's to remove the natural starches and sugars from the plant. This simple step is crucial because it makes the bamboo less attractive to pests and prevents mold growth later on.

- Drying: The treated strips are then carefully kiln-dried to reduce their moisture content from around 40% to a stable 8-12%. This is perhaps the most critical step. If bamboo is dried too quickly it will crack, and if it's not dried enough it will warp later. Precision here is key.

How is bamboo produced?

The term "bamboo product" is very broad. You're trying to figure out how the same starting material can end up as both a soft shirt and a hard, solid countertop.

After initial harvesting and drying, bamboo production splits into two main paths. For solid goods, strips are glued and pressed together. For textiles, the bamboo is broken down completely, either mechanically into fibers or chemically into a pulp to create rayon.

Thinking about these two paths is the easiest way to understand bamboo manufacturing2. It's like cooking with a single ingredient, like a potato. You can slice it and fry it to make chips (a solid form), or you can boil it and mash it into a smooth paste (a broken-down form). Both are potato, but the process and the final result are completely different. The same logic applies to bamboo.

Path 1: Creating Solid Bamboo Goods

This is the path we take at BambooPackage to make our beautiful lids and containers. This process aims to keep the natural structure of the bamboo intact as much as possible.

- Method: It involves taking the dried strips we talked about, applying a strong, low-VOC adhesive, and then laminating them together under immense heat and pressure.

- Result: This creates large, stable blocks or panels that look and feel like a high-quality hardwood. This "bamboo wood3" can then be machined with precision CNC tools into complex shapes, just like traditional wood.

- Benefit: This method preserves the natural grain and strength of the bamboo.

Path 2: Creating Bamboo Textiles

This path is all about breaking the bamboo down to get to its basic cellulose fibers.

- Method: This can be done mechanically (crushing and combing out fibers, which is rare and expensive) or chemically (dissolving the bamboo in solvents to create a pulp, then extruding it as a thread). This chemical process creates what is known as viscose or rayon.

- Result: A very soft, silky thread that can be woven into fabric.

- Trade-off: The chemical process loses all of the bamboo’s original structure and natural properties.

How is bamboo wood manufactured?

You're designing premium products and need to understand the material's engineering. "Laminated strips" sounds simple, but you know the details matter for strength, appearance, and quality.

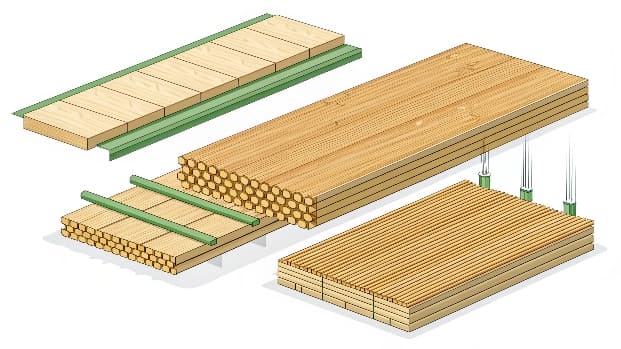

Bamboo wood is an engineered product made by bonding dried bamboo strips under heat and pressure. The orientation of these strips during lamination—laid flat, on their sides, or shredded and compressed—creates different aesthetics and technical properties for the final board or block.

As a designer like Jacky, you appreciate how materials are constructed. This is where bamboo manufacturing becomes really interesting. It's not just gluing strips together; it's an engineering choice that defines the final product's character. We can control the look and feel of our bamboo lids4 just by choosing a specific lamination technique. It gives us incredible design flexibility while using the same raw material.

Engineering with Bamboo Strips

Once we have our kiln-dried bamboo strips, the magic of lamination begins. This is how we build a strong, stable material that’s ready for precision carving. There are three primary methods:

| Lamination Type | Description | Visual Appearance |

|---|---|---|

| Horizontal | Strips are laid flat, one on top of the other, like a stack of paper. | Wide grain pattern, showing the natural "knuckles" or nodes of the bamboo stalk clearly. |

| Vertical | Strips are turned on their sides and glued together. | Narrow, linear grain pattern with fewer visible nodes. Creates a more uniform, modern look. |

| Strand-Woven | Strips are shredded into strands, mixed with resin, and compressed in a mold under extreme heat and pressure. | A marbled, varied grain pattern. This method produces the hardest and most durable type of bamboo wood. |

After lamination, we have a large block or sheet of engineered bamboo wood. From here, we use CNC machines5 to cut, carve, and shape the material into the final product, whether it's a perfectly threaded cap for a cosmetic bottle or a large piece of furniture.

Is bamboo natural or manufactured?

Your brand wants to use "natural" materials. But with processes like lamination and chemical treatments, you wonder if bamboo still counts or if it crosses the line into a manufactured product.

Bamboo is a natural raw material that is then manufactured into a final product. Think of it like leather or wood. The cowhide and the tree are 100% natural, but they must be processed—tanned or milled—to become usable. The source is natural, the result is manufactured.

This is a question I think about a lot. At BambooPackage, our motto is "Naturally Beautiful." We believe the beauty comes from the natural source material, but that beauty is only made useful through careful and responsible manufacturing. One cannot exist without the other. The key is that our manufacturing process is designed to celebrate and preserve the natural qualities of the bamboo, not disguise them or break them down into something else entirely.

A Spectrum of Manufacturing

It’s not a simple "yes" or "no" question. The best way to think about it is on a spectrum.

-

Minimally Processed (Most Natural): On one end, you have products like a whole bamboo stalk used as a decorative element or the solid bamboo lids4 we create. Here, the manufacturing involves cutting, shaping, and laminating, but the inherent look, feel, and structure of the natural bamboo6 are maintained and are the star of the show.

-

Heavily Processed (Semi-Synthetic): On the other end of the spectrum, you have bamboo viscose7/rayon fabric. Here, the natural bamboo6 stalk is completely dissolved through a chemical process. The final fiber has no resemblance to the original plant. While its origin is natural cellulose, the final form is a purely manufactured material.

Ultimately, bamboo is always a natural resource. The final product is always manufactured. As a designer, your job is to choose the product where the manufacturing process respects the natural origin of the material.

Conclusion

Bamboo's manufacturing transforms a natural grass into diverse, high-performance products. Understanding the difference between solid wood lamination and chemical fiber processing is key to making truly sustainable design choices.

Understand why bamboo is considered a sustainable material and its environmental benefits. ↩

Explore the intricate steps involved in bamboo manufacturing to understand its sustainability and quality. ↩

Discover the unique properties of bamboo wood and how it compares to conventional hardwoods. ↩

Explore the manufacturing process of bamboo lids and their applications in design. ↩

Explore the role of CNC machines in shaping bamboo products with precision and efficiency. ↩

Delve into the natural origins of bamboo and its transformation into various products. ↩

Understand the process of making bamboo viscose and its characteristics as a fabric. ↩