Are you worried your cosmetics might not survive the journey to customers? Durable, eco-friendly packaging is key, but not all materials perform the same under shipping stress.

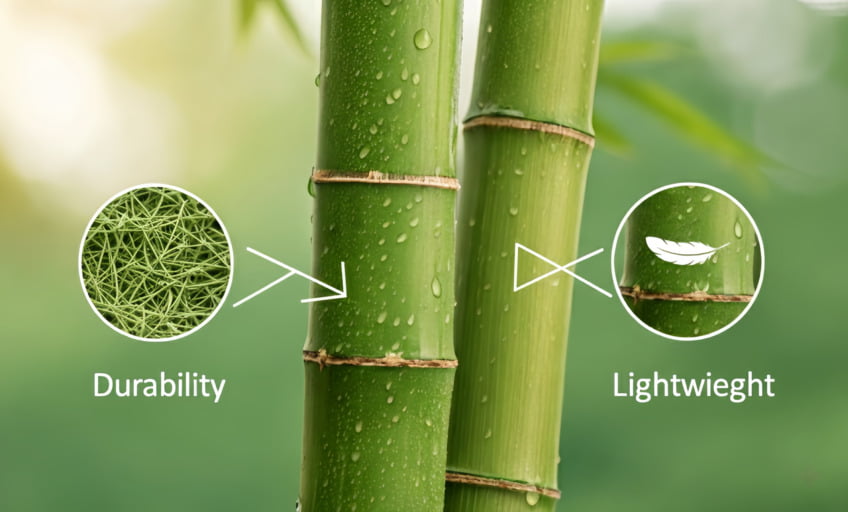

Bamboo packaging1 is highly durable for shipping cosmetics. Its fibrous structure absorbs impact and prevents damage, while lightweight properties keep shipping costs low. Hybrid models2 improve resistance to moisture and temperature, offering superior protection during transit.

Shipping cosmetics safely is a challenge I face with every new brand collaboration. I’ve watched bamboo packaging prove effective, but I know its limits. Bamboo absorbs shocks and looks great, yet pure bamboo needs finishing touches to cope with rough shipping environments. Insights from my work with ECO-BAMBOO show superior results when designers use hybrid solutions. Let’s unpack how bamboo handles impact, moisture, and combines with other materials to deliver high durability for cosmetics.

How effectively does bamboo packaging protect cosmetic products from impact and environmental stresses during transit?

Cracked bottles and crushed compacts can ruin a customer’s first impression. No one wants their luxury cosmetics damaged before use.

Bamboo packaging1 provides strong impact resistance thanks to its natural fibers. It can absorb energy from drops and bumps, shielding fragile products. Bamboo also offers partial resistance to humidity and temperature if treated, but hybrid inserts enhance protection against environmental stresses.

Protection during shipping starts with sturdy structure. When I compare bamboo to common packaging like cardboard or plastic, bamboo’s fibrous layers stand out for soaking up shocks. That’s why bamboo packaging seldom cracks or dents when dropped. Yet, every time I ship internationally, factors like humidity on the ocean or season changes test the packaging. Untreated bamboo absorbs moisture, which may affect both aesthetics and strength. On one project, I watched a cosmetics line travel through humid Asian ports and saw untreated bamboo start to warp. After switching to barrier-coated bamboo or using hybrid packaging with water-resistant liners, the problem vanished. Now, I always recommend these enhanced approaches for best protection.

| Material | Impact Resistance | Moisture Resistance | Weight | Cost Impact |

|---|---|---|---|---|

| Standard Bamboo | High | Medium (when treated) | Low | Lower fees |

| Cardboard | Low | Low | Low | Neutral |

| Recycled Plastic | Medium | High | Moderate | Higher fees |

| Hybrid Bamboo | Very High | Very High | Low | Lower fees |

What are the limitations of bamboo packaging's durability, especially concerning moisture and temperature fluctuations during shipping?

Shifting climates and unpredictable weather make shipping a minefield. Packaging must endure both drops and environmental extremes.

Bamboo packaging1’s key limitation is sensitivity to moisture and temperature swings. Without protective coatings or liners, bamboo may warp, swell, or crack during shipping. Hybridization and moisture-resistant finishes can significantly boost its durability in harsh conditions.

Bamboo stands up to impact, but weather is a different challenge. Once, I shipped untreated bamboo packaging for a summer cosmetics launch, only to see some containers warped by monsoon humidity. That experience taught me to always push for SGS- or ROSH-certified moisture barriers. Bamboo itself is porous; moisture can seep in, causing swelling or even mold if shipping takes too long. Rapid temperature shifts—from cold storage to hot delivery vans—can cause bamboo to crack without extra protection. Today, I tell clients that true durability needs hybrid approaches. Pairing bamboo shells with recycled plastic interiors or laminated liners keeps contents dry and stable from factory to doorstep.

| Limitation | Untreated Bamboo | Treated Bamboo | Hybrid Packaging |

|---|---|---|---|

| Moisture Resistance | Poor | Good | Excellent |

| Crack Resistance | Moderate | Good | Excellent |

| Warp Resistance | Low | High | Very High |

Can hybrid bamboo packaging solutions offer enhanced protection for cosmetic products during rigorous shipping and handling?

Mixing materials to get the best of both worlds sounds smart, but does it really protect delicate cosmetics better?

Hybrid bamboo packaging boosts both impact and environmental resistance. It pairs bamboo’s natural strength with inserts or liners made from recycled plastic, silicone, or barrier-coated materials. These hybrid designs reduce risk of warping, cracking, and moisture infiltration during rigorous shipping.

My most rewarding projects come from pushing packaging design. I partner with cosmetic brands that ship globally, and I always advocate for hybrid designs because they work. For one luxury brand, we built bamboo exteriors over recycled plastic cushioned inserts. The packaging sailed through humidity in Southeast Asia and freezing ports in Scandinavia, keeping glass bottles intact. It passed all drop tests and retained aesthetic appeal—key for luxury cosmetics. Hybridization also fits ECO-BAMBOO’s philosophy: high performance without abandoning sustainability. Certifications like SGS or ROSH back up our claims and ensure materials coexist seamlessly. By integrating hybrid bamboo packaging, my clients consistently report fewer returns and happier customers.

| Feature | Pure Bamboo | Hybrid Bamboo |

|---|---|---|

| Impact Protection | High | Very High |

| Moisture Resistance | Moderate | Very High |

| Temperature Resilience | Moderate | Very High |

| Aesthetic Value | High | High |

| Sustainability3 | High | High |

How does bamboo packaging's strength and lightweight nature impact shipping costs and product integrity for cosmetics?

Many brands worry that eco-friendly packaging will raise costs or compromise safety. Does bamboo help or hurt the bottom line?

Bamboo packaging1’s lightweight and strong structure reduces shipping fees while protecting cosmetics from breakage. Lower weight translates to less fuel use and reduced carbon emissions, making shipments greener and cheaper without sacrificing product integrity.

Early in my packaging career, shipping costs were always a headache. Heavy packaging meant bigger fees and higher carbon footprints. Switching to bamboo was a game changer. Its strength-to-weight ratio means boxes stay light without losing durability. For every 1,000 units shipped, brands save hundreds in transport costs. Less fuel burned means better sustainability. If I compare bamboo to glass or dense plastics, bamboo shines for both cost and eco-value. My clients now ask for lighter, SGS-certified designs that maximize product safety but are easy on wallets and the planet. At ECO-BAMBOO, I design hybrid bamboo models to balance weight, strength, and style for global shipments.

| Metric | Bamboo Packaging | Glass Packaging | Plastic Packaging |

|---|---|---|---|

| Average Unit Weight (g) | 55 | 220 | 75 |

| Shipping Cost (Per 1000) | Low | Very High | Medium |

| Breakage Rate | <1% | 10% | 3% |

| Environmental Footprint | Minimal | High | Moderate |

Conclusion

Bamboo packaging1 offers tough, sustainable protection for cosmetics in transit. When treated or hybridized, it handles impact, moisture, and temperature while lowering shipping costs for eco-conscious brands.