A single faulty bottle1 can damage your brand’s image and lead to costly returns or safety risks. Catching defects early is crucial for a consistent, reliable product line.

Check for uneven thickness2, seams, bubbles3, cracks, sink marks4, warping5, and color issues—these defects in plastic and glass can weaken lotion bottles and cause leaks, contamination, or breakage.

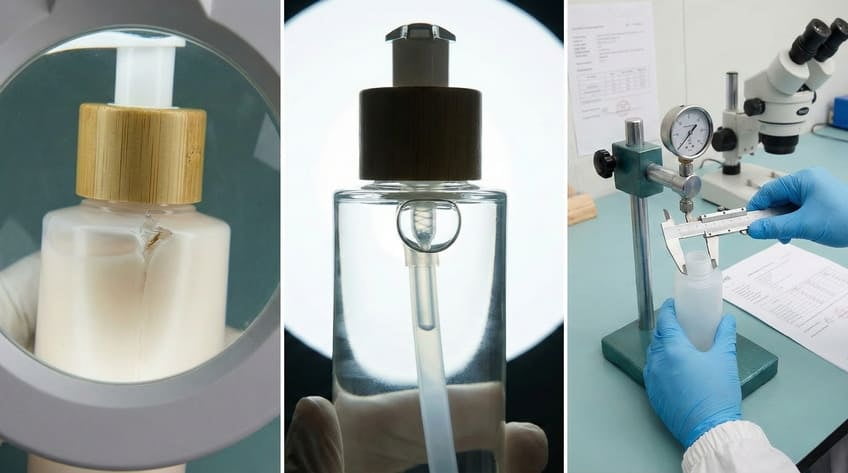

Every new production run at ECO-BAMBOO starts with visual and mechanical inspections6. I have seen how a missed defect—whether a weak seam in plastic or a glass bubble—can slip through to customers and erode trust. That is why our process always includes strict third-party testing7 and immediate reporting of anomalies to production teams.

What are the most common defects in plastic bottle manufacturing?

Plastic bottles often show uneven wall thickness, sink marks4, warping5, visible mold seams, incomplete filling (short shots), and surface blemishes. These defects compromise both durability and appearance.

During site visits and QC audits, I look for these telltale flaws by holding bottles up to the light, squeezing for weak points, and inspecting seams. Often, resin mix or temperature issues are to blame. Sink marks signal cooling problems, while warping5 often comes from improper demolding speed. Even a single blemish on a premium bamboo-collared bottle is flagged for further review.

Plastic Defects Table

| Defect | Description | Impact |

|---|---|---|

| Sink marks | Indentations in surface | Affects strength, leaks |

| Warping | Twisted or misshaped bottle | Poor fit, shelf appeal |

| Uneven thickness | Thin/Thick walls | Weak points, leaks |

| Visible seams | Lines from mold joints | Cosmetic, weak spots |

| Short shot | Incomplete molding | Bottle failure |

| Surface blemish | Spots or foggy area | Poor appearance |

What are the critical quality defects to look for in glass bottles?

Inspect for bubbles%%%FOOTNOTE_REF3%%%, stones (unmelted bits), cracks, uneven walls, [surface waviness](https://www.climateseal.com/wavy-glass/?srsltid=AfmBOorfHYKb-x-TdCw1ukL04RIpYLZ-PBpBcdR4-o8xDdsWUGXqR7G)8, and sharp points, as these threaten both product safety and visual appeal in glass packaging.

One ECO-BAMBOO cosmetic client saw a spike in leakage complaints traced to tiny cracks formed during rapid cooling. Our switch to SGS-certified bamboo/glass bottles with extra wall inspections eliminated the issue. Each bottle is now checked for clarity, even thickness, and completely smooth surfaces—critical for luxury skincare and safety alike.

Glass Defect Table

| Defect | Description | Risk |

|---|---|---|

| Bubbles | Air trapped inside glass | Weakens structure |

| Stones | Solid bits of unmelted glass | Breakage, contamination |

| Cracks | Visible fractures or lines | Splintering, leaks |

| Uneven thickness | Variations in wall size | Poor durability |

| Surface waviness | Irregular texture | Cosmetic flaws |

| Sharp points | Untrimmed edges | Injury risk |

What causes bubbles3 and uneven thickness2 in glass bottle production?

Bubbles and uneven thickness2 often result from uneven mixing of glass, rapid temperature changes, poor mold maintenance, and dirty or worn-out molds during bottle production.

I’ve toured factories where temperature control was inconsistent between batches and saw bubbles3 form as cooled glass trapped air. Mold cleaning schedules, insufficient mixing, or rushed cooling cycles are the usual suspects. Only factories with robust systems—like ECO-BAMBOO’s QC steps and third-party audits—keep defects at bay.

Common Causes Table

| Issue | Cause | Solution |

|---|---|---|

| Bubbles | Air in molten glass, poor mixing | Slow cool, clean molds |

| Uneven thickness | Fast cooling, uneven mold temps | Controlled cooling, QC |

| Stones | Unmelted raw glass | Screen materials, temp |

How do you identify quality control issues9 in cosmetic packaging?

Spot quality control issues9 by thorough visual inspection of every batch, squeeze and stress test10 bottles, check for consistent color, weight, and label fit, and require documented third-party compliance.

At ECO-BAMBOO, detailed checklists and SGS/ROSH certifications mean every bottle—from bamboo-collared plastic to premium glass—meets client standards. We train partners to spot weak seams, off-color plastics, and misshaped openings. Reporting even minor leaks or glitches prevents bigger supply chain headaches and product returns.

QC Methods Table

| Method | Process | Why It Works |

|---|---|---|

| Visual check | Look for bubbles3, seams, color | Finds obvious defects |

| Mechanical test | Squeeze/fit/weight checks | Ensures durability |

| Third-party cert | SGS/ROSH audit and testing | Confirms compliance |

| Stress test | Drop and leak trials | Exposes hidden issues |

Conclusion

Spotting defects—like bubbles3, cracks, or warping5—keeps lotion bottles safe and brands trusted. Insist on QC, strong standards, and certifications for packaging that looks and works perfectly every time.

Understanding the consequences of a faulty bottle can help you protect your brand's reputation. ↩

Explore the reasons behind uneven thickness to improve your production quality. ↩

Find out the causes of bubbles to prevent defects in your glass products. ↩

Understanding sink marks can help you identify and rectify production flaws. ↩

Understanding the causes of warping can help you improve your manufacturing process. ↩

Learn how these inspections can enhance your product's reliability and safety. ↩

Discover the benefits of third-party testing for ensuring product quality and compliance. ↩

Explore the implications of surface waviness on product aesthetics and safety. ↩

Learn effective methods to spot quality control issues and maintain product standards. ↩

Learn how stress tests can reveal hidden issues in your packaging. ↩